A Facelift for Old Fixtures

Ever wonder as you move your palm over a favorite Edwardian-era pedestal sink—feeling the glaze gone sandpapery over the decades, noting a new chip—if there’s a fix: a kind of Botox for bathtubs? Here’s a quick course on your refinishing options.

Vintage cast-iron fixtures, from sexy Roman tubs to workaday kitchen sinks, get their ultra-smooth, chemical-resistant surface from porcelain enameling, a process not perfected until the late 1880s. Also called vitreous enamel, it’s essentially powdered glass sifted onto a super-heated casting, then fired multiple times in an oven to produce a coating 35 to 60 mils (thousandths of an inch) thick and slick as a window pane. Owners of damaged, collectible-quality fixtures usually opt for a new, sprayed-on coating. The service is available in most locales as franchises and individual businesses. Materials and methods vary, but the basic process, as explained by Charles Wachter, owner of Porcelite in Beltsville, Maryland, is straightforward.

For, say, an antique clawfoot tub brought to Wachter’s shop, refinishing begins with a good bath, as it were. All drains, faucets, and fittings have to come off, and so does soap scum (re moved with solvent and scraper. “When clawfoots come in,” says Wachter, “you can imagine they’ve got multiple coats of paint on one side, nothing but rust on the other, so we apply chemical stripper, then scrape, grind, and sand all that off.”

Next comes prepping the surface. First a technician must etch the vitreous enamel by applying hydrofluoric acid, a powerful chemical that eats microscopic peaks and valleys into the enamel for tooth, or anchorage, to which the new paint can bond. After rinsing the tub, the technician fills any scratches, chips, or other surface defects. Porcelite uses a polyester filler, the same as used for automotive body work; large gouges are repaired with fiberglass followed by filler. After the miscellaneous repairs are cured, the whole tub is sanded, feather-edging the filler.

Now the tub is ready for finishes. First Porcelite sprays on epoxy primer in one thin coat. When the primer has cured, it’s followed by the final finish. “We use an acrylic polyurethane enamel,” says Wachter, “especially for tubs, because there’s potential for expansion and contraction.” Wachter, who has been in business since 1961, adds: “Epoxy coatings are wonderful, but they have a potential to yellow as they age.” At Porcelite, the spray materials for each project are proportioned in advance to produce a 3- to 4-mil dry film thickness.

“Of course, everything is low-VOC these days,” says Wachter. The final finish is applied in three to four coats, at 15-minute intervals or so depending on humidity, producing a uniform, shiny finish. Special projects may be lavished with a light buffing a few days later.

Just like after a human nip-and-tuck, a refinished tub needs a little extra attention—no cleaning with abrasive scouring powders. But with care the finish will typically last eight to 10 years, sometimes longer.

“It’s a lot of work to move a tub in and out of a house,” says Wachter, so the majority of Porcelite’s projects are out-patient, so to speak—done in the client’s house. Refinishing in the home saves the effort of disconnecting and transporting the fixture, but it has challenges. All the adjacent surfaces have to be meticulously masked off. Caulking around the tub is removed, then reapplied when the finish is set. Complex fixtures like clawfoot tubs can get tricky. “The inside is no problem,” says Wachter, “but we can coat the outside only to the ‘vanishing point’ where it curves into the wall.”

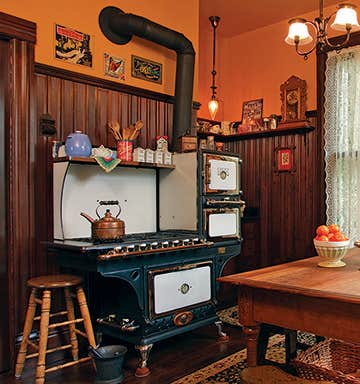

Wachter also does a regular business refinishing salvaged fixtures in his shop. Porcelite has refinished stoves and collectible refrigerators. The shop also gets into custom color. “If a customer brings us a good color sample,” says Wachter, “we can usually hit it right on.”

Real Reporcelainizing

Specialty businesses that finish, or refinish, sheet metal with true porcelain enamel are rare enough—most tackle signs or appliance parts. Those equipped to handle cast iron and tub- size projects are very hard to find. One is Custom Ceramic Coatings (customceramic.com) in Illinois. Owner John Ballantyne says he receives projects from all over the country. After prepping, the fixture is coated with the enamel mixture of glass and other ingredients—called “slip” in the trade—then fired in a furnace at over 1400 degrees F. While porcelain coating is often used in industry for such needs as lining heavy pipes, Ballantyne makes a specialty of limited-run, custom orders, such as manufacturing prototypes. Coating engine exhaust manifolds for auto and motorcycle restorers is a surprisingly common commission. “We just finished one for a 1928 Pierce Arrow,” he explains. Before you take this route, remember:

- You’ll have to remove the fixture, then ship it to and from the shop, which may be quite expensive for a large piece of cast iron.

- Typically, the old finish will have to be completely removed by sandblasting, adding to the overall cost.

- Color matching is not a sure thing, because precise matches for porcelain finishes made decades ago (even white) are tricky.

DIY

Owners may prefer the economy of refinishing a fixture themselves; a variety of paint- on and spray-on tub-and-tile kits are available for $50 or so. Most are epoxy-based, meaning brush-on paints requiring thorough mixing of coating and hardener—but that’s not where the fussy hand work stops. No less than for a professional job, meticulous prep is key; the instant water finds a way under the coating, its days are numbered. The typical kit demands scrupulous scrubbing of the fixture a couple of times with special cleansers (some supplied, some user-bought), then an equally painstaking sanding to “kill” the slick surface. Also, you can’t escape removing tub caulking and surgically masking off fittings and surroundings. The cosmetic success of the actual paint job relies on avoiding drips and “curtains.” That said, for those undaunted by refinishing antiques, a tub-and-tile redo may be just the answer for a little-used guest bath sink.

Gordon H. Bock, Assoc. AIA, the former longtime editor of Old-House Journal, is a contributing editor at Traditional Building magazine, co-author of The Vintage House, and a writer/editor for many architectural periodicals and books. An instructor with the National Preservation Institute and the historic preservation program at Drew University (1997-2016), he travels widely giving keynote speeches and professional seminars and as a technical and architectural consultant.

The hidden pen behind some popular names, Gordon is a national expert in architectural content as well as a communications professional. With a MS in Publishing, he has over 25 years of experience managing and developing in-house publications, magazines, online extensions, and related franchise media. For more information, contact Gordon at ghbock@comcast.net.