Seamless Thinking: Options for Sink & Countertop

During the early 20th-century bungalow era, sinks and countertops came together in a way that’s still practical.

Harriet Beecher Stowe was 40 years ahead of her time when she installed a fully plumbed, undermount sink with adjacent counter space in her 1870s kitchen. She even had the foresight to tuck three ample drawers into the cabinet base.

Stowe (who, with her sister Catharine Beecher, advocated better working conditions for women at home) clearly understood the importance of a seamless kitchen workspace. She cared about beauty, too: The built-in pine cabinet that held the sink was paint-grained to resemble chestnut.

The crucial relationship between the sink and its countertop was subject to many innovations in the first decades of the 20th century. Basins had been used for millennia, but whoever came up with the idea of the undermount sink—a basin attached more or less flush with the countertop—conjured up one of the most useful kitchen fixtures ever.

Period examples in copper, zinc, stainless steel (with us since 1913), and nickel-coated metals anticipate styles still found in contemporary kitchens. Rounded or oval basin sinks began appearing in pantries in the late 19th century. These are still an attractive and historically accurate style for secondary, prep, and pantry areas—especially in copper, a material common in the era and now promoted for its antiseptic properties.

Since many early sinks were fabricated to order, it was an easy jump to fashion an all-in-one unit. While some early integral sink counters could be crude (a galvanized tin sink mounted under a wood drainboard wasn’t likely to survive intense use for long), others offered elegance and durability.

The most famous of these, and among the most seamless, is probably the German silver sink (actually made of nickel with other metals). Available with both single and double basins, these sinks made a smooth curve down from the metal countertop without any cracks or crevices to collect dirt. The most graceful feature molded drainboards and an S-shaped curve dividing the basins. Freestanding examples rested on finely detailed metal legs.

Such nickel-coated sinks were expensive and consequently rare. A more affordable option that quickly caught on was the cast-iron sink coated with enamel. Most of the refinished original and reproduction cast-iron sinks now available are coated with high-fired porcelain.

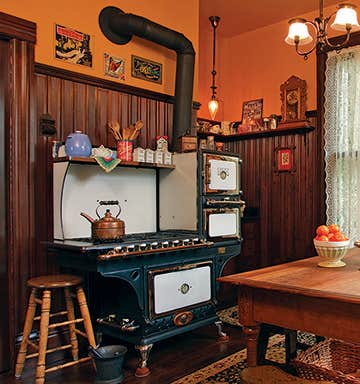

Like its cabinet counterpart, the Hoosier, the freestanding cast-iron sink is an all-in-one food prep space. The design is ingenious, offering rounded corners, rolled rims, and seamless surfaces from edge to high backsplash. In sync with the goals of the late 19th-century “sanitary movement,” it offers fewer places for dirt and germs to hide.

In a mammoth-size example, one or two integral sinks are flanked on either side by expanses of porcelain fabricated with drainage ribs or grooves to direct water into the sink. The sink stands on shaped, tapering porcelain legs; a wall-mounted faucet fits into the high backsplash. Variations produced for decades range from single-basin wall-hung sinks with one or no side counters to legless versions intended for mounting on top of cabinets.

Rare in the period, apron-front or farmhouse-style sinks have their origins in earthenware and fireclay sinks, and probably owe a debt to the flat-bottomed dry sink as well. Hard-fired ceramic fireclay sinks originated in England; Shaws (still in business) began producing them in 1897. Modern-day iterations of the farmhouse sink come in almost every possible material: hammered and patinated copper, soapstone, slate, stainless steel, fireclay, and porcelain. Most, however, are undermount or overmount sinks, meaning there are still small gaps between sink and counter.

Freestanding porcelain sinks may be seamless, but even the largest offer finite counter space. What better solution than to turn to one of the oldest materials used in kitchens (stone) and one of the newest (concrete) to produce almost seamless countertops with integral sinks? Laser-guided machinery makes it easy to cut stone so that a sink all but disappears into a counter of any size. It’s possible to shape a sink out of a single piece of soapstone, and even flat-bottomed sinks can be precision-cut to drain perfectly.

Like clay but far stronger, concrete is manipulated by artisans into perfectly smooth counters that segue effortlessly into sink basin—with, if desired, dividers that pick up the vaunted S-shape of a circa 1915 nickel-alloy sink. In another welcome trend, fabricators are adding drainage grooves to counters made not just of stone and wood, but also metal, concrete, and such manmade materials as quartz blends. They say what goes around comes around, and that’s never been truer than for kitchens of the Arts & Crafts revival.

Mary Ellen Polson is a creative content editor and technical writer with over 20 years experience producing heavily illustrated know how and service journalism articles, full-length books, product copy, tips, Q&As, etc., on home renovation, design, and outdoor spaces.