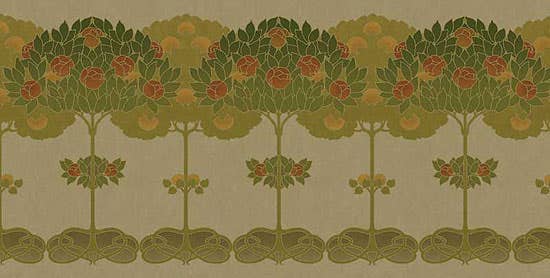

Brett Johnson wasn’t yet 20 when Chris Efker of Craftsmen Hardware asked him for help building his home, but he quickly found he had a knack for the Greene & Greene-inspired pieces Efker sought. He ultimately made all the light fixtures for the coppersmith’s house.

Soon, Johnson was building and selling Arts & Crafts lighting and furniture on his own, often replicating pieces to scale from photographs. Twenty years later, he’s internationally known for his fine interpretations of Greene & Greene-style lighting, such as the Gamble House dining-room chandelier, with intricate leaded glass suspended from a large mahogany canopy.

Johnson employs the wide variety of skills and techniques demanded by a Greene & Greene-inspired light fixture—from making the copper foil to shaping the wood elements. “Every corner of every piece of wood is softened by hand,” he says. “It rolls back on itself and has a certain grace to it.”

His first light was a table lamp, done through trial and error, which he still owns. After that one he visited Greene & Greene houses to examine fixtures and furniture in person. He generally works in the same woods used by early Arts & Crafts practitioners: quartersawn oak and quartersawn mahogany, also known as ribbon grain, with ebony for accents. He makes every component in every light fixture himself, including selecting, cutting, and fitting glass; creating the copper foil to hold glass in place; and cutting and shaping the leather suspension straps found on some fixtures.

Johnson estimates he finishes 100 to 200 pieces in a year. He finds he works best on his own, with just a shop dog for an assistant, because “it takes years to teach somebody how to do all of this.”

BRETT JOHNSON

Craftsmen Studio

Keytesville, MO

(660) 973-4608

craftsmenstudio.com

Mary Ellen Polson is a creative content editor and technical writer with over 20 years experience producing heavily illustrated know how and service journalism articles, full-length books, product copy, tips, Q&As, etc., on home renovation, design, and outdoor spaces.